Checking out the Future of Plastic Injection Molding in the Manufacturing Industry

Checking out the Future of Plastic Injection Molding in the Manufacturing Industry

Blog Article

Understanding the Basics of Plastic Shot Molding Processes

Plastic injection molding serves as a keystone of modern-day production, supplying a methodical approach to generating intricate elements with precision. Exploring these essential elements can expose exactly how even minor changes can lead to considerable enhancements in production end results, increasing questions about the possibility for development in this established procedure.

What Is Plastic Injection Molding?

Plastic shot molding is a commonly made use of production process that transforms polycarbonate and thermosetting materials into precise and intricate forms. This strategy is favored for its ability to generate high volumes of identical get rid of outstanding precision, making it an important technique in numerous markets, including auto, consumer products, and clinical tools.

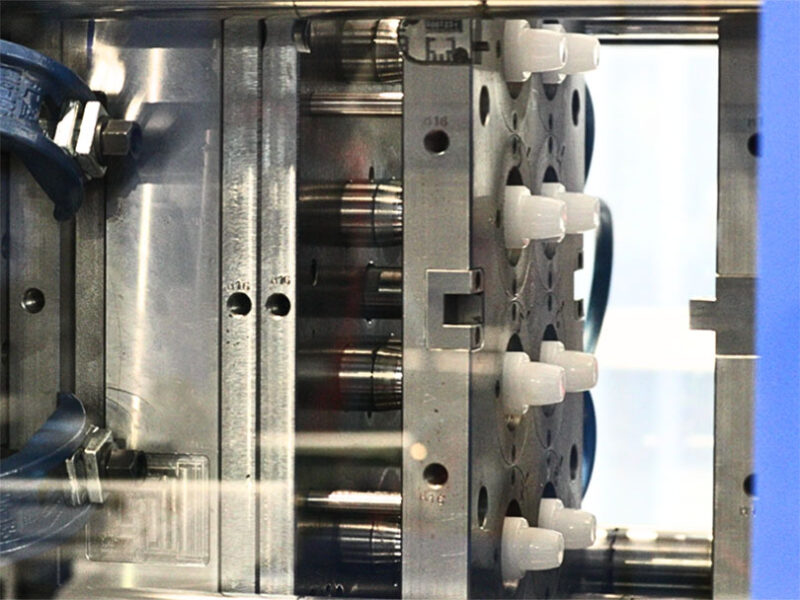

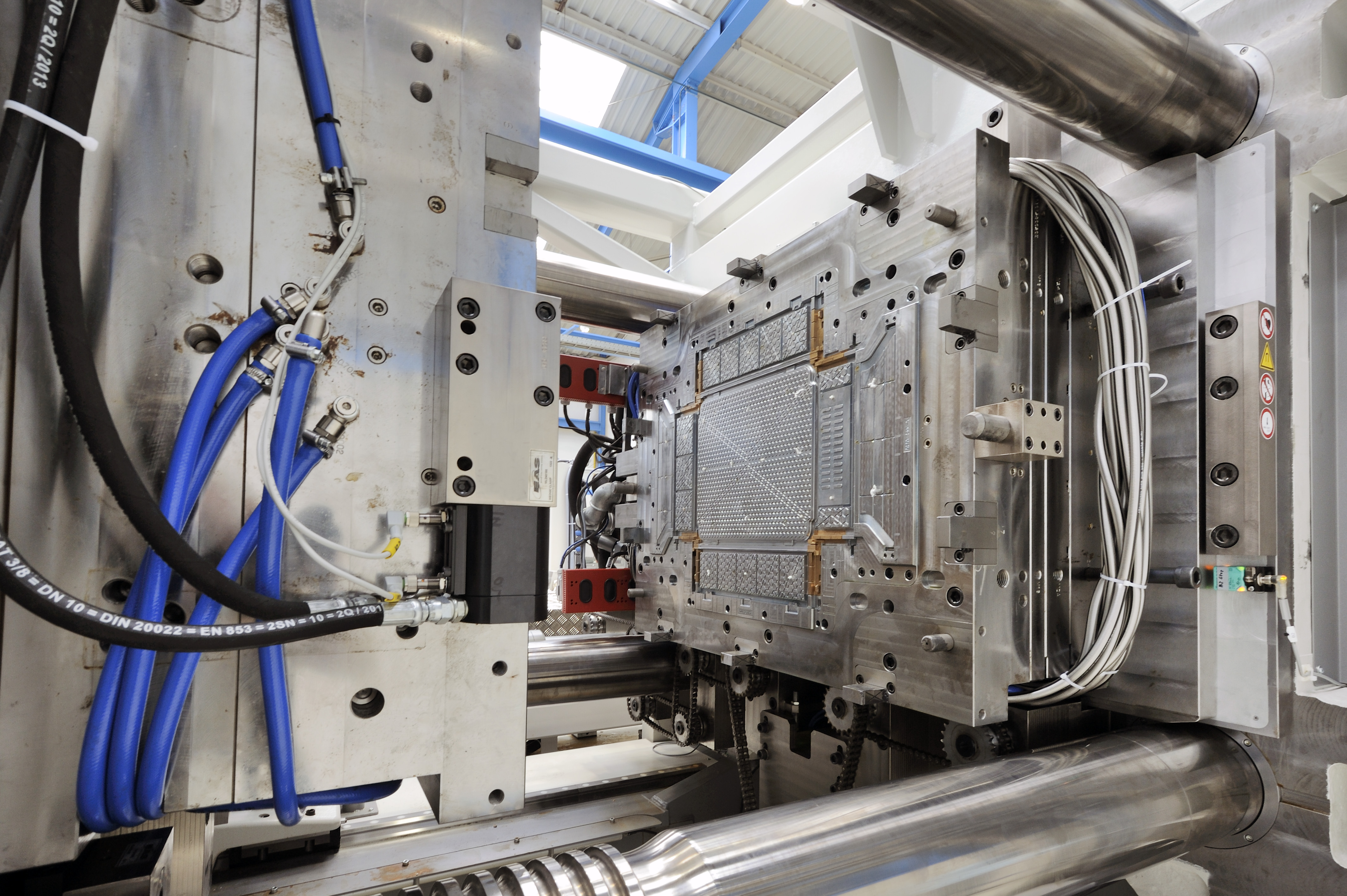

The process includes thawing the chosen plastic material and injecting it right into a mold and mildew under high pressure. The mold, created to the requirements of the desired part, permits the liquified plastic to take shape as it strengthens and cools down. Once the material has solidified, the mold and mildew is opened up, and the finished component is ejected.

Plastic shot molding supplies several benefits, consisting of minimized waste, consistency in production, and the ability to include elaborate designs that may be testing with various other manufacturing methods. Furthermore, it supports a broad variety of products, each giving one-of-a-kind buildings that can be customized for details applications. As industries continue to innovate, plastic shot molding stays at the leading edge, making it possible for the growth of innovative products that meet evolving consumer needs.

The Shot Molding Refine

The shot molding process is an advanced technique that involves several key phases to generate high-grade plastic parts. At first, plastic pellets are fed into a heated barrel where they are melted right into a thick liquid. This molten plastic is after that injected under high pressure right into a precision-engineered mold and mildew, which shapes the material right into the wanted type.

Once the mold and mildew is filled up, the plastic is permitted to strengthen and cool, taking the shape of the mold and mildew tooth cavity. Cooling time is essential, as it affects the cycle time and the last buildings of the molded component. After adequate cooling, the mold and mildew opens, and the ended up element is expelled utilizing ejector pins.

Materials Used in Injection Molding

Various materials can be used in the injection molding process, each offering distinct residential properties that accommodate details applications. One of the most commonly used products consist of thermoplastics, thermosetting plastics, and elastomers.

Thermosetting plastics, like epoxy and phenolic resins, undertake a chemical change during the healing process, leading to an inflexible, stringent structure. These products are ideal for applications needing high warmth resistance and architectural integrity, commonly used in electrical insulators and vehicle components.

Elastomers, consisting of silicone and rubber-based products, provide versatility and durability. Their one-of-a-kind residential or commercial properties make them ideal for applications that demand flexibility, such as gaskets and seals.

Furthermore, specialized materials like bio-based plastics and compounds are getting grip for their ecological benefits and enhanced performance qualities, widening the extent of shot molding applications in numerous sectors. Understanding the homes of these products is vital for picking the ideal kind for specific projects.

Benefits of Shot Molding

Shot molding sticks out as an extremely effective manufacturing process that provides numerous advantages for generating intricate get rid of precision. Among one of the most substantial benefits is the ability to create intricate layouts that would certainly be difficult or impossible to attain with other methods (Plastic Injection Molding). The process permits for in-depth functions and tight resistances, guaranteeing premium components

In addition, shot molding is known for its quick production capabilities, making it an optimal selection for high-volume production. Once the mold and mildew is produced, parts can be generated rapidly, decreasing preparations and boosting overall productivity. This performance not only decreases production prices however also supplies an one-upmanship on the market.

The versatility of products used in shot molding further improves its allure. A wide variety of thermoplastics and thermosetting polymers can be employed, allowing makers to select products that ideal meet their details requirements, consisting of strength, versatility, and warmth resistance.

In addition, the process reduces waste, as excess product can frequently be reused and recycled. This sustainability facet contributes to a decreased ecological influence, making shot molding an accountable production option. Overall, the advantages of shot molding make it a recommended approach for many markets.

Aspects Influencing Item Top Quality

While numerous factors can influence product quality in injection molding, comprehending these aspects is vital for attaining optimal outcomes. Key aspects include product option, refining criteria, and mold and mildew layout.

Product choice plays a crucial duty, as various polymers display special properties that affect flowability, strength, and thermal security. Poor product option can result in problems such as warping or insufficient dental filling.

Handling specifications, including temperature, stress, and cycle time, should be carefully controlled. Variants in these settings can result in disparities in part measurements and surface area finish. For instance, excessively high temperature like it levels might create deterioration of the polymer, while insufficient pressure can result in short shots.

Mold and mildew style is equally crucial, as it figures out the flow of the molten plastic and the cooling procedure. Badly made molds might result in uneven air conditioning prices, leading to residual anxieties and dimensional inaccuracies.

Conclusion

To conclude, plastic shot molding functions as a critical manufacturing procedure that enables the efficient manufacturing of top quality parts. Mastery of the shot molding procedure, consisting of the understanding of products and the impact of numerous aspects on product high best site quality, is necessary for accomplishing ideal results. The advantages of this approach, such as cost-effectiveness and style versatility, further underscore its value throughout several industries, solidifying its standing as a preferred choice for high-volume manufacturing.

Plastic injection molding serves as a keystone of contemporary production, offering a methodical strategy to creating complex parts with precision.Plastic injection molding uses a number of benefits, including reduced waste, uniformity in production, and the capacity to integrate intricate layouts that may be testing with other making methods (Plastic Injection Molding). As sectors read what he said continue to introduce, plastic injection molding continues to be at the forefront, making it possible for the advancement of innovative products that fulfill developing customer needs

The injection molding procedure is a sophisticated technique that involves several essential stages to produce high-quality plastic parts.In final thought, plastic shot molding serves as an important manufacturing process that makes it possible for the effective manufacturing of top quality parts.

Report this page